Granite

Granite is a natural stone, one of the hardest available, and it has all of the unmistakable beauty that Mother Nature can provide. Granite counters are available in both slabs and in tiles, and each piece — particularly the slabs — will have a wide variety of unique colors and grains.

Being a natural stone, granite will vary slightly in color and pattern between slabs. Whenever possible, you should examine the actual slabs that will be used in your kitchen, not just samples, and then verify that the installer has enough material from the same initial block so that there will be minimal variations of color between the pieces.

How granite is installed

Once your cabinets are in place, the countertop fabricators will make a site visit to create templates. Using thin strips of wood, sheets of corrugated plastic or other materials, they’ll carefully cut, fit, and glue up an exact replica of your cabinets, including the location of sinks and other cutouts. These exact templates are then taken back to the fabrication shop, where they’re used to cut the slabs to a precise match.

Once the slabs have been cut, an installation team will do the final fitting. Small adjustments will be made on-site as needed, then the counters will be installed using a sealant, usually silicone, that adheres them to the top of the cabinets.

Given the weight of the slabs and the limitations of slab lengths — typically no longer than 10 feet — most larger kitchens will have seams between the slabs. While a good installer will situate the seams and match the slabs to minimize the appearance of the seams, bear in mind the seams will still be visible. Seams will show less on darker and more uniform granite, and will show more on material that has more pattern and veining.

Granite pros and cons

On the plus side, granite is a smooth, highly durable natural stone with one-of-a-kind beauty. It’s easy to wipe clean and is very hygienic if properly sealed. It works well with virtually any type of home or kitchen style, and since it’s popular, it will typically add resale value.

On the negative side, granite is porous, so it can be stained by certain oils, even things like butter, and other foods. It needs to be properly sealed, and the sealer needs to be re-applied periodically, typically every one to three years, depending on the stone and the usage.

Being a natural stone, it’s not always uniform in color or pattern, so the slabs can vary from the color and pattern seen in samples, and the seams may be visible. There may be fissures in the stone that can be damaged by heat.

Finally, it’s very heavy, so there may be additional shipping costs, installation costs, and even reinforcement for some types of cabinets.

Engineered quartz

Quartz counters offer striking natural beauty, lots of color and pattern choices, and a natural appearance, while at the same time eliminating some of the drawbacks of natural stone. As such, it’s becoming an attractive alternative to granite. Some of the manufacturers of quartz countertops include Silestone, Cambria, Zodiaq and CaesarStone.

Engineered quartz countertops are made from about 93 to 95 percent natural ground quartz, with the remaining 5 to 7 percent consisting of resins and pigments.

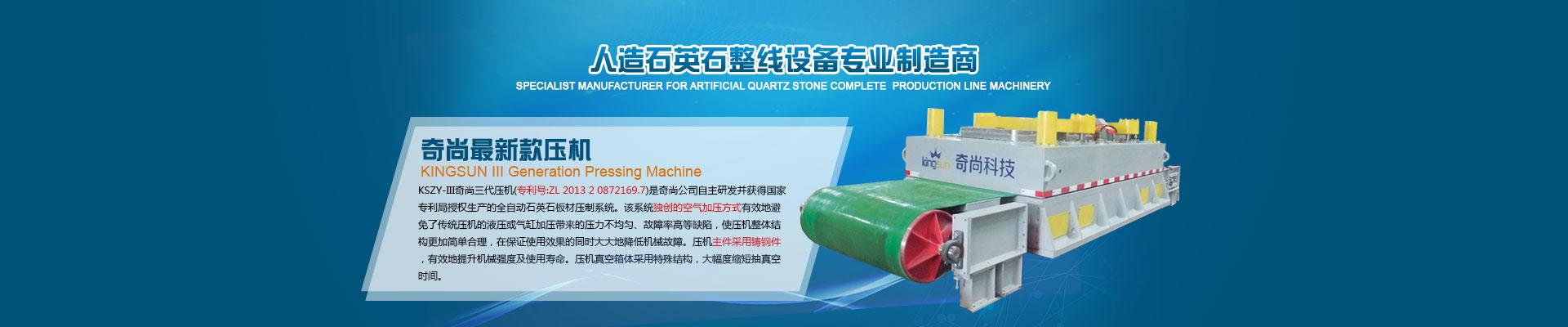

The carefully blended mixture is molded into slabs, which are vibrated and compressed while a vacuum removes air. This process eliminates air pockets and creates a hard and dense material that’s then heat-cured, rolled to specific thicknesses, and polished to a beautiful sheen.

How quartz is installed

The installation process for quartz counters is much the same as for granite. After the cabinets have been installed, the fabricators make a site visit to make up templates, then the templates are used at the fabrication shop to custom cut the slabs. The slabs are then adhered to the cabinets, usually with silicone.

As with granite, larger kitchens will typically require seams between some of the slabs. A good installer will carefully place the seams where they will be the least visible, and then blend color putties to make the seams much less obtrusive. Because quartz counters are more uniform in color and pattern than granite, the seams typically are less visible.

Quartz pros and cons

Quartz counters are hard and dense, are resistant to knife cuts, and since they aren’t porous they’re much more stain resistant and don’t require ongoing application of sealers. They’re also more heat resistant, since there aren’t any fissures. They’re hygienic and easy to clean.

Thanks to the careful selection and blending of the quartz crystals and the addition of specific pigments, engineered quartz counters come in a variety of colors, with grain patterns that range from fairly soft to a lot more bold. The colors and patterns are relatively uniform, so the seams are a lot less visible than with many granite installations.

As with granite, the look of quartz blends with virtually any style of home and kitchen, and you have the added advantage of a manufacturer’s warranty, which natural stone doesn’t have.

On the down side, quartz counters may actually be more expensive than some types of granite. And for some people, quartz may not have the striking beauty found in some natural granite counters.

Address:North Xingye Road, Shishan Town, Nanhai District, Foshan City, Guangdong , China

Address:North Xingye Road, Shishan Town, Nanhai District, Foshan City, Guangdong , China Tel:+86-13928648965 (Mr Lu)

Tel:+86-13928648965 (Mr Lu) E-mail:info@fskingsun.com

E-mail:info@fskingsun.com